Advance utility asset management with AI desktop inspections

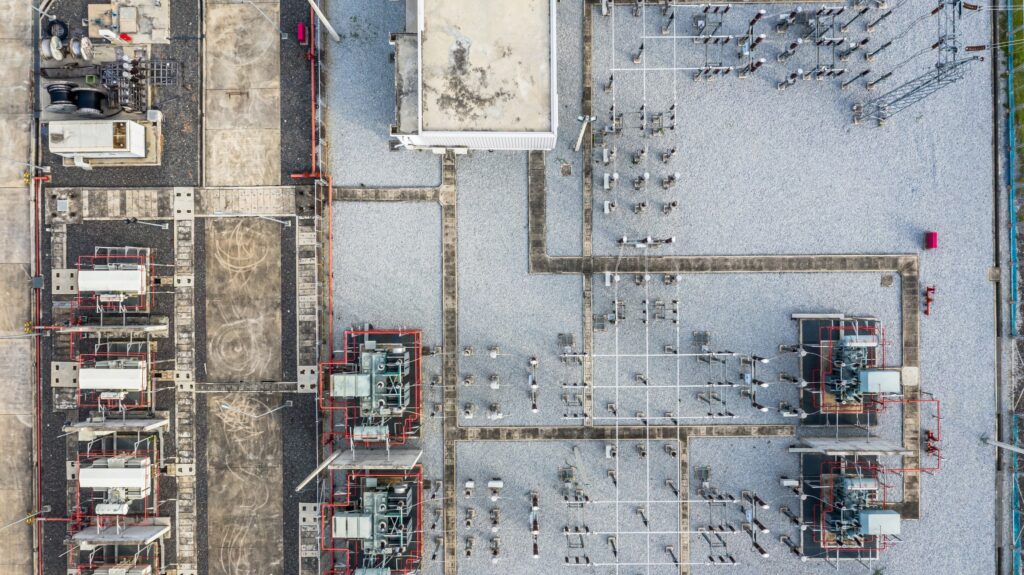

Modern utilities face an array of challenges, from outdated inspection methods to maintaining an aging infrastructure. Traditional inspection methods can force inspectors to drive to remote sites, document their findings manually, and potentially overlook critical issues due to human error.

These traditional approaches can lead to operational inefficiencies, increased safety risks, and higher maintenance costs. As utilities aim to meet rising expectations for reliability and safety, an urgent need for more effective inspection methods has become apparent.

AI technologies, specifically computer vision and machine learning, are poised to become transformative tools for addressing these challenges. Powered by AI, drones and other sensors capture large amounts of inspection data, with the potential to fully automate inspection processes in the future. AI also facilitates comprehensive asset data collection, which is crucial for effective asset management and long-term maintenance planning. This innovation can enhance the accuracy and scope of inspections while significantly reducing the time and costs associated with manual processes. Modernizing inspection methods with AI is crucial for maintaining the integrity of utility assets in an increasingly complex environment while improving operational efficiency.

Drivers for adopting advanced desktop inspections

Aging infrastructure

The utility sector is grappling with the challenge of aging infrastructure, with some grids well over 100 years old. As equipment ages, it becomes more susceptible to wear and tear, exacerbated by increasingly severe weather conditions brought about by climate change. Aging equipment demands frequent, granular inspections to identify potential issues early, preventing failures that could lead to costly repairs and significant service disruptions, and to collect detailed asset data for effective asset management.

Wildfire mitigation plans

Regulators in states with high fire risks, such as California, require utilities to implement and maintain wildfire mitigation plans (WMPs) to formalize the assessment and addressing of wildfire risks. Desktop inspections enable utilities to enhance their WMPs by proactively identifying hazards and optimizing resource allocation to ensure resilience and public safety.

Regulatory and safety-related pressures

Legal mandates require utilities to enhance their inspection methods, emphasizing the need for more robust and precise monitoring systems. Traditional inspection methods pose significant safety risks, as they often involve inspectors physically accessing dangerous or hard-to-reach areas.

Legacy inspection limitations

Historical inspection methods, including visual inspections and helicopter flyovers, are increasingly proving insufficient for modern utility asset management. These methods are often plagued by a lack of proper documentation, with outdated paper records and spreadsheets creating a gap between physical realities and documented data. Moreover, traditional methods struggle to capture real-time changes in assets, leading to a disconnect between what is recorded and what exists in the field.

Key performance indicators (KPIs) for desktop inspections

Macro-level KPIs

Macro-level key performance indicators are essential for assessing the overall effectiveness of desktop inspections across a utility’s entire asset portfolio. One crucial metric is the number of assets inspected per month. This indicator provides insight into the scale and reach of the inspection program, highlighting the efficiency gains from transitioning to AI-supported desktop inspections. A higher number of inspected assets indicates a more comprehensive maintenance strategy.

Another significant macro-level KPI is the shift from reactive to proactive maintenance. By identifying and addressing potential issues early through frequent and detailed inspections, utilities can shift from a reactive to a proactive maintenance approach. This pivot reduces the frequency and severity of unexpected failures and lowers costs related to emergency repairs and service disruptions. Monitoring this KPI helps utilities quantify the financial benefits and operational improvements achieved through advanced inspection methods.

Micro-level KPIs

Micro-level KPIs focus on the performance and effectiveness of individual inspectors and the inspection process itself. One important metric is the efficiency of individual inspectors, measured by the number of assets inspected per hour. This KPI helps evaluate how well inspectors are using the tools and technologies available to them, identifying opportunities for further training or process optimization.

The accuracy of inspections is another critical micro-level KPI, often assessed through supervisor approval rates. This metric indicates the reliability and precision of the inspections, ensuring that issues are correctly identified and documented. High approval rates from supervisors reflect a well-functioning inspection system with consistent and accurate reporting.

Tracking the number of issues identified and resolved per month, quarter, and year provides valuable insights into the effectiveness of the inspection program. This indicator helps utilities measure the impact of their inspections on overall asset health and maintenance outcomes. A higher number of resolved issues indicates a proactive approach to asset management, where potential problems are addressed before they escalate into major failures.

Evolution of desktop inspections

As utility asset management continues to evolve, the future of desktop inspections promises significant advancements. Technologies such as drone-mounted cameras, computer vision (CV), and machine learning are driving progress through the initial, middle, and long-term stages of modernizing utilities’ inspection methods.

Initial stages

The initial stages of modernizing desktop inspections involve integrating drone cameras to capture high-quality images of utility assets. Drones equipped with advanced cameras enable human teams to cover extensive areas efficiently, providing detailed visuals that are essential for accurate inspections. This integration reduces the need for inspectors to access remote or hazardous locations, improving safety and operational efficiency.

Using structured forms and standardized data entry is crucial to ensuring data consistency in this stage. By standardizing how inspection data is recorded and stored, utilities can maintain high-quality datasets that are easy to access and analyze. This structured approach reduces the risk of human error and enhances the reliability of the information gathered, laying a solid foundation for more advanced stages of the inspection process.

Middle stages

As the inspection process evolves, the development of comprehensive inspection guides and training programs for inspectors becomes essential. These guides provide detailed instructions on what to look for during inspections and how to document findings accurately and in accordance with established standards. Proper training ensures that inspectors can effectively use new technologies and follow standardized procedures, leading to more consistent and reliable inspection results.

During these middle stages, the increasing use of AI to automate image analysis becomes a focal point. AI algorithms, trained on vast amounts of data, can quickly and accurately identify potential issues in the images captured by drones. This automation not only speeds up the process, but also enhances the accuracy and scope of the inspections, allowing for the detection of problems that might be missed by human inspectors.

Long-term vision

The long-term vision for desktop inspections includes fully automated drone inspections with pre-programmed flight paths (which require FAA approval). These drones can operate autonomously, capturing images of utility assets without the need for constant human intervention. This level of automation significantly reduces the time and labor required for inspections, allowing utilities to conduct more frequent and more comprehensive assessments.

Also being explored is the possibility of continuous monitoring through fixed cameras installed on assets. These cameras could provide real-time data on the condition of the asset, enabling utilities to detect changes and potential issues as they arise and bolstering their ability to maintain and manage assets proactively, while also facilitating the collection of up-to-date asset records.

Challenges and considerations

Implementing advanced desktop inspections in utility asset management comes with its own array of challenges and considerations. Addressing these issues is crucial for maximizing the benefits of new technologies and ensuring the success of inspection programs.

Data quality and consistency

High-quality data enables utilities to make informed decisions, plan maintenance schedules accurately, and ensure the reliability and safety of their assets. Standardizing data entry across different teams and systems can be difficult, and inconsistencies in how data is recorded can lead to gaps and errors that undermine the overall effectiveness of the inspection process.

Limitations of AI and computer vision

AI models require precise training data and well-defined inspection parameters to function effectively. Without high-quality, representative datasets, the accuracy and reliability of AI-driven inspections can be compromised.

Misconceptions about AI’s capabilities are not uncommon; it is not a magic solution that can operate without human oversight. Human expertise is essential for interpreting AI findings, making judgment calls, and ensuring that the technology is applied correctly.

Operational and logistical issues

Drones must be operated within FAA constraints, and careful planning and coordination are required to ensure that they capture the necessary images from the right angles. Furthermore, both inspectors and drone operators require specialized knowledge and training to be able to gather accurate and useful data.

Looking to the future of utility inspections

Adopting AI-powered desktop inspections marks a transformative shift in utility asset management. By integrating technologies such as drones and computer vision, utilities can overcome the limitations of traditional inspection methods, ensuring more accurate, efficient, and safe operations. This proactive approach allows utilities to manage their assets more effectively, mitigate wildfire risks, reduce maintenance costs, improve overall service reliability, and ensure comprehensive asset data collection. Embracing such innovations positions utilities to meet future challenges and maintain robust infrastructure in an increasingly complex environment.

About the Authors

Solutions Architect Jeff Lovington has been product manager of Logic20/20’s computer vision team for a major West Coast utility since 2021. He also brings nearly a decade of experience in the telecom industry, building cellular network design and deployment software.

Scott S. Nelson is a Senior Technical Architect with over 20 years of experience consulting on robust and secure solutions in areas such as multi- and hybrid-cloud, system integrations, business process automation, human workflow management, and quality assurance innovation.